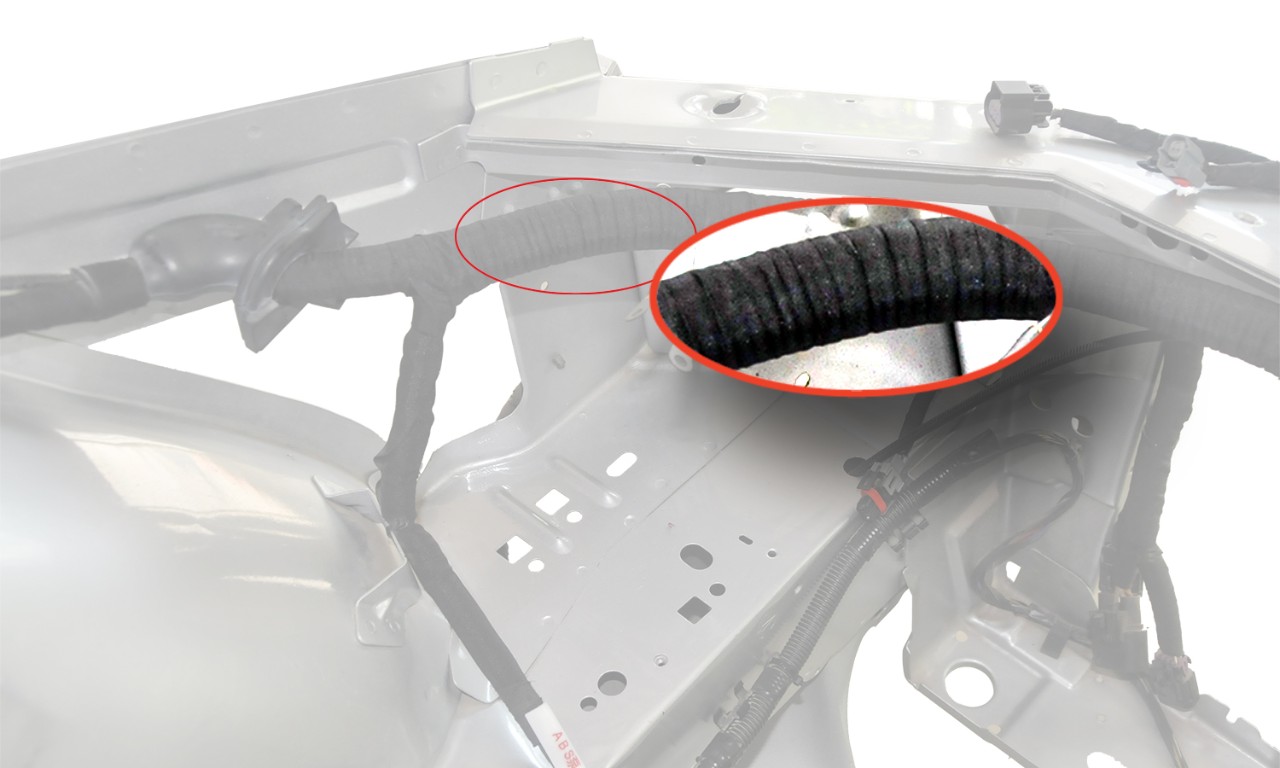

Avery Dennison Yongle is successfully addressing the challenge of automotive electrical noise occurring from wire harnesses with a portfolio of protective tapes that help reduce noise-producing vibration in applications.

Selecting the right tape for the application is central to the overall solution. As one of the few designers, producers and suppliers of pressure-sensitive adhesive tapes approved by OEM and Tier manufacturers for wire harness applications, Avery Dennison Yongle is well-equipped to help provide the right product for your application needs.

Our abrasion-resistant tapes range from standardized and customized PVC tape to cloth, nylon and sleeve tapes. The tapes meet OEM and Tier suppliers’ standards and can reduce wire harness production costs through expert product selection. Their stable release force and adhesion contribute to harness wrapping efficiency and can improve wire harness appearance.

Abrasion-resistant tapes provide strong adhesion with no edge lifting or residue and deliver stable automotive wire harness protection. Customers can choose tapes with different abrasion and temperature resistance to meet an application’s specific needs. Tapes are available in different colors for identification purposes.

For more information on Avery Dennison Yongle automotive wire harness abrasion resistance tapes, visit our online product selector or contact our adhesive tape experts today.