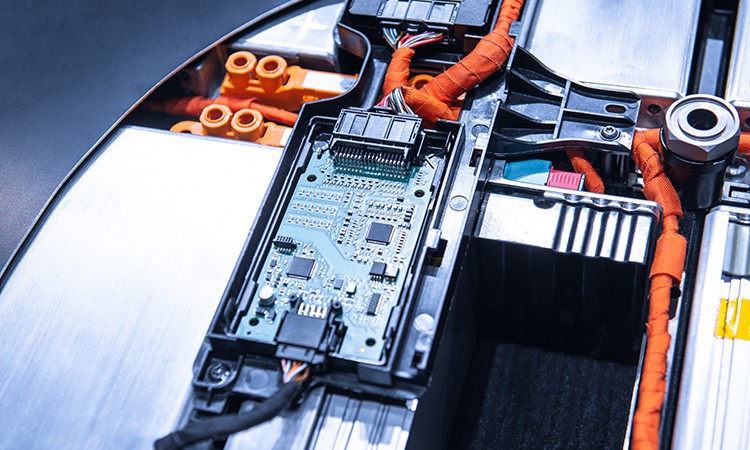

Wire harnesses play the vital role of bundling overlaps and crossovers. Even a slight wire harness design or assembly flaw can cause electromagnetic wave interference. In order to avoid this interference and ensure stable signal transmission, engineers specify EMI shielding materials that deliver good wire harness wrapping and shielding.

At the same time, with the increasing popularity of supercharged engines, the heat-reflective material also serves to isolate and reflect in high temperature areas.

Avery Dennison Yongle provides EMI shielding and heat reflective tapes that meet the standards of OEMs for both traditional fuel and new energy vehicles (NEV). These high-performance shielding materials can effectively prevent electromagnetic wave interference. The heat-reflective tapes can also solve temperature and abrasion resistance challenges in engine compartment wire harnesses.

While Avery Dennison Yongle’s aluminum foil tapes and laminated materials are mainly used for EMI shielding and heat reflection in communication transmission lines and joints, they also meet OEM standards for wire harness signal, magnetic field, thermal reflection and isolation applications. The tapes can be either manually or automatically wound.

For more information on Avery Dennison Yongle automotive wire harness tapes for EMI shielding and heat reflection applications, visit our online product selector or contact our adhesive tapes experts today.