Avery Dennison Yongle provides lightweight tapes with high-quality substrates such as PVC and cloth. Automotive OEMs and Tier suppliers are sourcing the tapes for their insulation, water and chemical resistance, and flame retardancy performance characteristics.

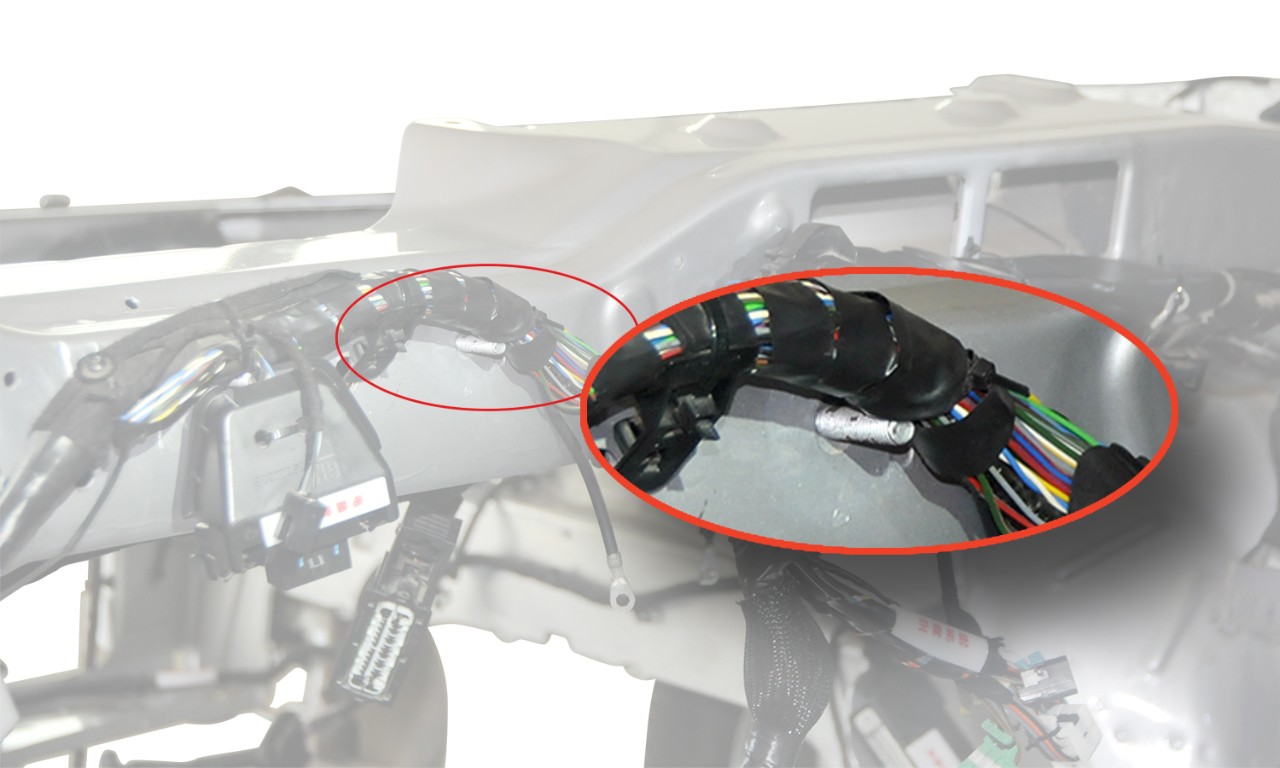

The tapes are color-coded to identify varying types of wire harnesses. They are widely used in instrument panel harnesses, engine compartment, door, light wire, ceiling and chassis wire harness.

Avery Dennison Yongle combines its adhesive and substrate components to satisfy an application's requirements for sound reduction, and temperature and abrasion resistance. Our bundling tapes’ stable release helps improve wire-harness processing and bundling efficiency. They deliver excellent bonding performance without edge lifting, flagging or oozing.

Our lightweight and low-VOC tapes help OEMs and Tier suppliers to provide vehicle owners with a more comfortable driving experience. We actively innovate, develop and upgrade our tape products for traditional fuel and new energy vehicles to meet the wire harness bundling needs of customers worldwide.

For more information on Avery Dennison Yongle automotive wire harness general bundling tape, visit our online product selector or contact our adhesive tape experts today.