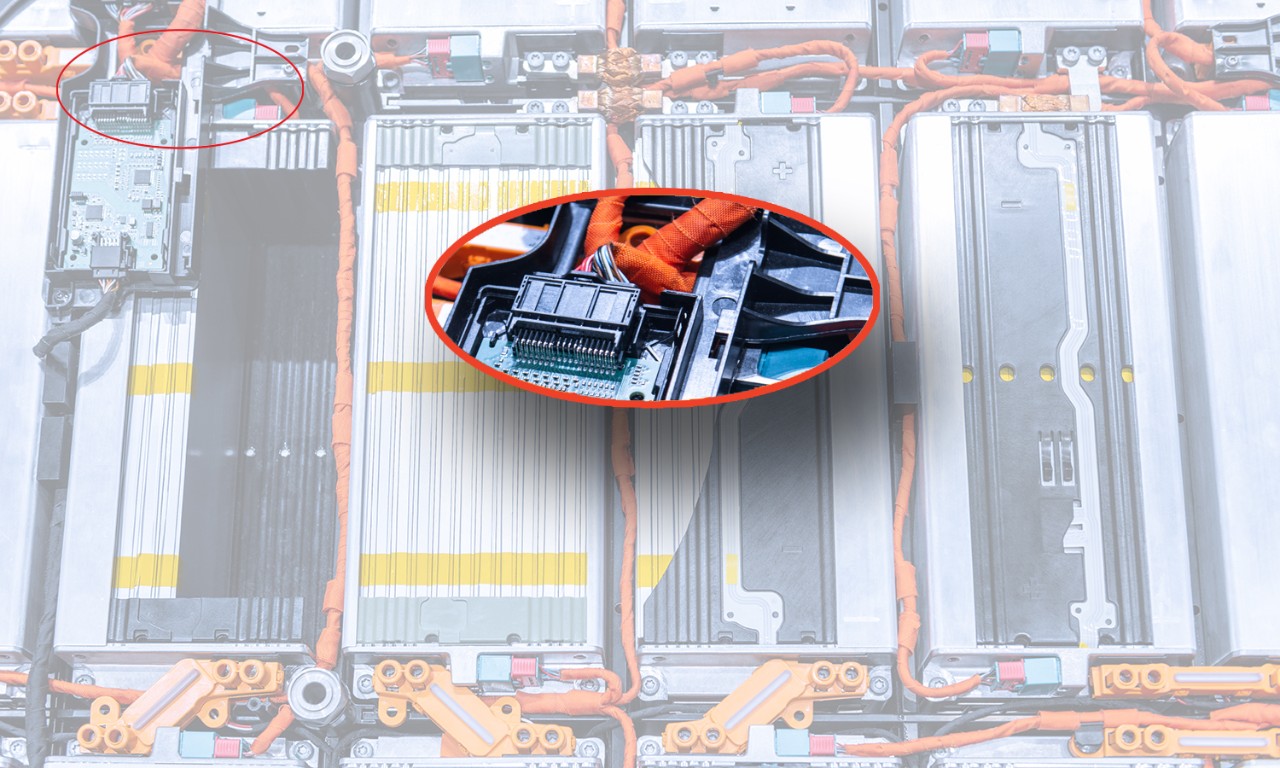

To meet their power and safety standards for transmitting signals and conducting electrical currents, NEVs need both high and low-voltage wire harnesses. Protective color-coded tapes with different levels of abrasion and temperature resistance are available to automotive designers from Avery Dennison Yongle for safe and secure wire harness wrapping.

Avery Dennison Yongle’s portfolio of high performance PVC and cloth tapes meet NEV’s stringent wire harness requirements. Automotive OEMs and Tier 1 manufacturers can specify the tapes for wrapping and protection in high and low-voltage wire harnesses and automotive speciality areas. The tapes will meet a particular harness’s insulation, flame retardance, labeling and warning, and EMI shielding needs.

Avery Dennison’s wire harness tapes are a product of the company’s technical know-how in adhesives and coatings. They exhibit strong bonding and adhesion, and highly stable unwinding. This enables manufacturers to apply the tapes efficiently in both manual and automated operations, reducing the total cost of wire harness assembly. The tapes’ strong bonding eliminates edge flagging and adhesive seepage, which improves NEV wire harness appearance.

For more information on Avery Dennison Yongle pressure-sensitive adhesive tapes for NEV wire harness, visit the online product selector or contact our adhesive tapes experts today.